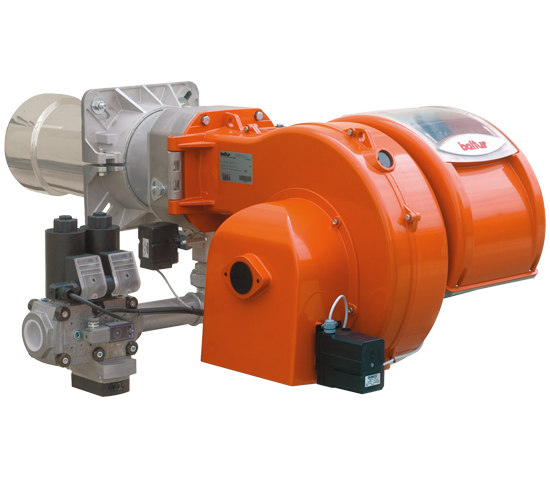

TBG 110 LX ME 50Hz

Code 17600020Progressive/modulating two-stage gas burners with low polluting emissions with electronic cam.

- Two-stage progressive.

- Electronic modulating control.

- Low NOx emissions.

- Home

- Products

- Burners

- Gas burners

- TBG 110 LX ME 50Hz

Technical data

Fuel

Natural Gas

Operation

Electronic Modulation

Minimum Thermal Power (kW) to ErP

180

Maximum Thermal Power (kW) to ErP

1200

Min flow rate (Sm³/H)

19

Max flow rate (Sm³/H)

127

Electric power supply type

AC

No. of Phases

3N

Power Supply Voltage (V)

400

Power Supply Frequency (Hz)

50

Fan Motor Power (kW)

1.5

Weight without packaging (kg)

67

Weight with packaging (kg)

88

Width (mm)

1070

Depth (mm)

800

Height (mm)

700

Technical Descriptions

Gas burner compliant with European standard EN676. Electronic operation at two progressive stages.

Continuous modulation operation by installing P.I.D. controller in the control panel (to be ordered separately with modulation probe).

Modulation ratio 1:6.

Gas burner with low NOx and CO emissions in accordance with European standard EN676: class 3.

Regulating combustion air and blast-pipe.

Combustion air intake with throttle damper. Air flow adjustment with electric servomotor.

Combustion air intake designed to achieve optimum linearity of the air gate opening.

Fully closing air damper on shutdown to avoid loss of heat through the chimney.

Maintenance facilitated by the possibility of removing the combustion head without having to remove the burner from the boiler.

Sliding boiler coupling flange to adapt the blast-pipe to the various types of boilers.

Easy maintenance thanks to the two-sides hinge which allows the removal of the combustion head without having to remove the burner from the boiler.

Device made of sound-absorbing material to reduce fan noise.

CE version gas train is complete with butterfly valve, operation and safety valve with electromagnetic drive, valve tightness control, minimum pressure switch, pressure regulator and gas filter.

Fail proof connectors for burner/gas train connection

Gas train exit: high/low.

Flame detection by ionisation electrode with connector for micro amp meter.

Control panel equipped either with display showing the working process and with the keyboard for the burner adjustment.

Electric control board in light alluminum alloy with IP55 protection rating

7-pole socket for burner electric and thermostatic supply.

4-pole socket for second stage control or for the connection of the PID electronic regulator.

Electrical system with protection rating IP44.

Documents

Public documents

Type summary

Revision

Publish Date

Languages

Reserved documents

Operating range

This product is part of the range TBG LX ME

Discover the entire seriesLogin

Burners

Burners

Websolute

Websolute